CLARUS®

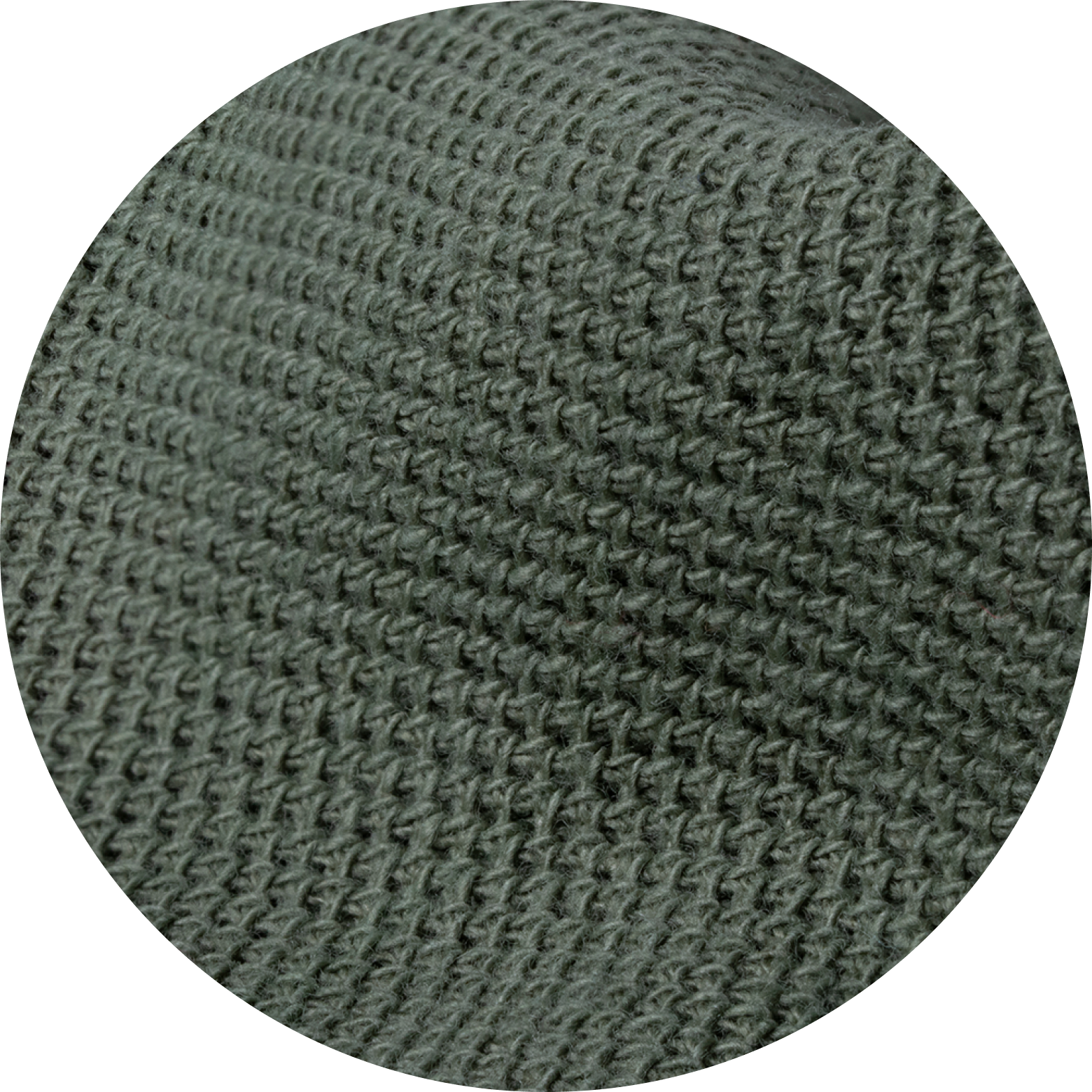

Tunable, precision-engineered fabrics

What is CLARUS®?

Tunable, precision-engineered fabrics – the natural solution for performance textiles built with earth-friendly fibers.

Unbelievably strong. Beautifully functional.

The technology behind CLARUS® breathes new life and strength into recycled fibers, powering performance at the highest level.

SCIENCE

Tunable, precision-engineered fabrics

CLARUS® textiles enable natural materials—like cotton, hemp, and wool—to compete at the highest levels of performance apparel. Think: the utility of synthetics from 100 percent natural sources. CLARUS® enhances virgin fibers and revitalizes recycled fibers, giving them all the strength of the first time around.

PERFORMANCE

The technology behind CLARUS® effectively lengthens and strengthens natural fibers, using green chemistry to create knits, wind resistant wovens and durable cotton canvas with high-value performance features.

APPLICATION

CLARUS® unearths new performance possibilities for natural fabrics, enabling our creative partners to design with for the highest functionality with earth-friendly fibers.

A platform of plastic-free performance materials to remake everything.

MIRUM®

Plant-based, plastic-free, not leather

CLARUS®

Tunable, precision-engineered fabrics

PLIANT™

Footwear outsoles with zero synthetics

TUNERA™

First-in-kind bioneutral foam